In order to initialize a conveyor you provide a profile of the material in the conveyor to Vensim. This profile shows how material will come out of the conveyor. Vensim automatically scales both the domain and range of the profile so that the total amount of material and the total initial conveyance time matches what is specified. The model convey1.mdl demonstrates this. For example using the Lookup:

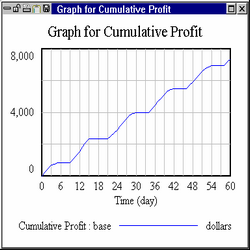

To initialize the DELAY CONVEYOR function would give the output (the input is zero so only initial material is ever output)

The total amount of stuff and the time over which the output occurs are determined by other arguments, but the shape is given by the Lookup. This makes it convenient to setup an approximate profiles, and this is usually all that is needed.

If you want to specify exactly what will come out at each time period you will need to use a more elaborate Lookup. For example using the lookup:

With an initial stock of 100 and delay time of 10 will give the output for detailed profile out of .

Time 0 1 2 3 4 5 6 7 8 9 10

5 10 20 10 15 20 10 5 5e-6 5 0

In this case is you were to change either the total stock or, more importantly, the delay time these exact numbers would not longer hold. Notice also the small roundoff error that occurs at time 8. Such noninteger results are to be expected when using DELAY_CONVEYOR.